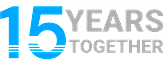

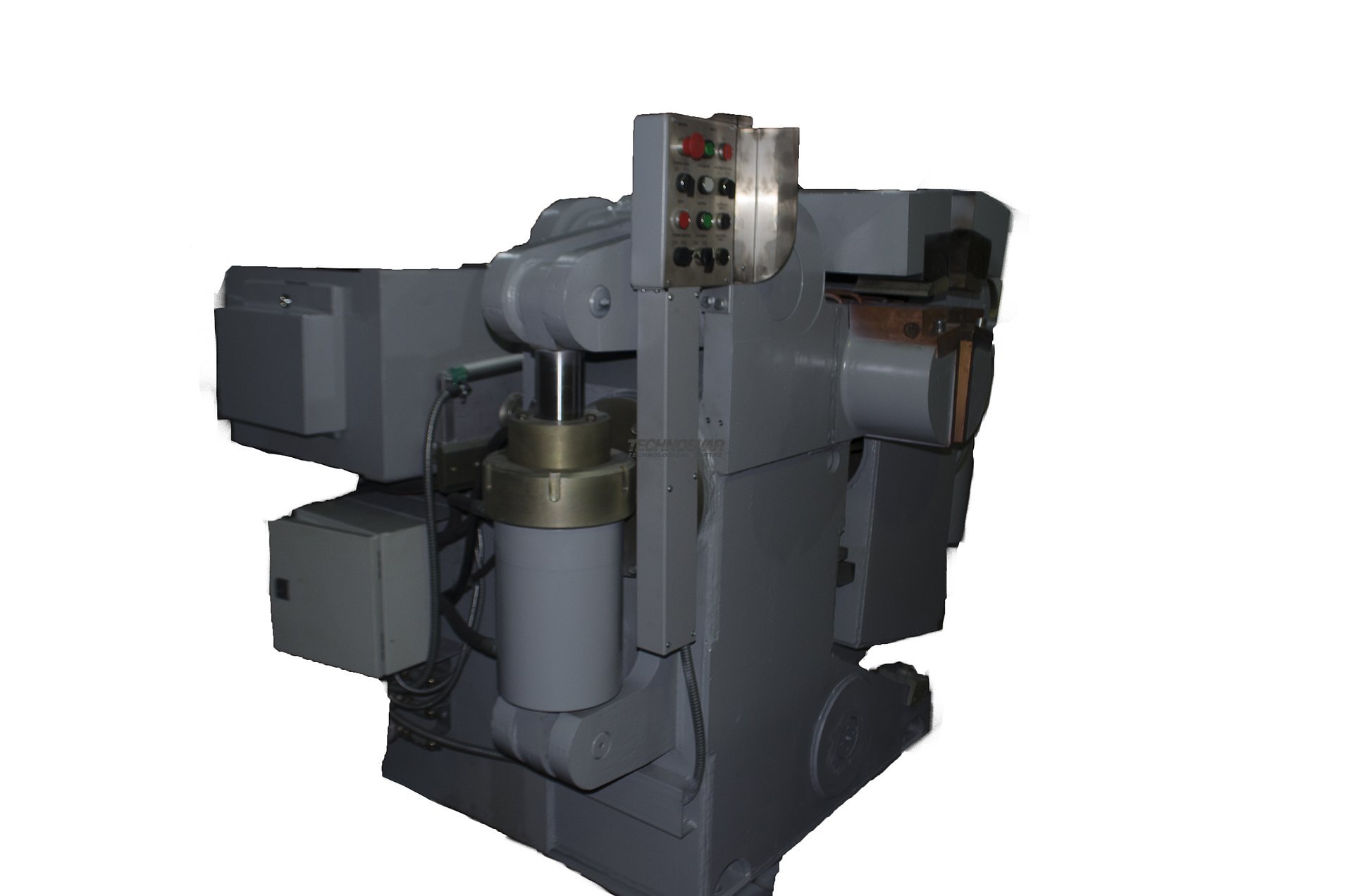

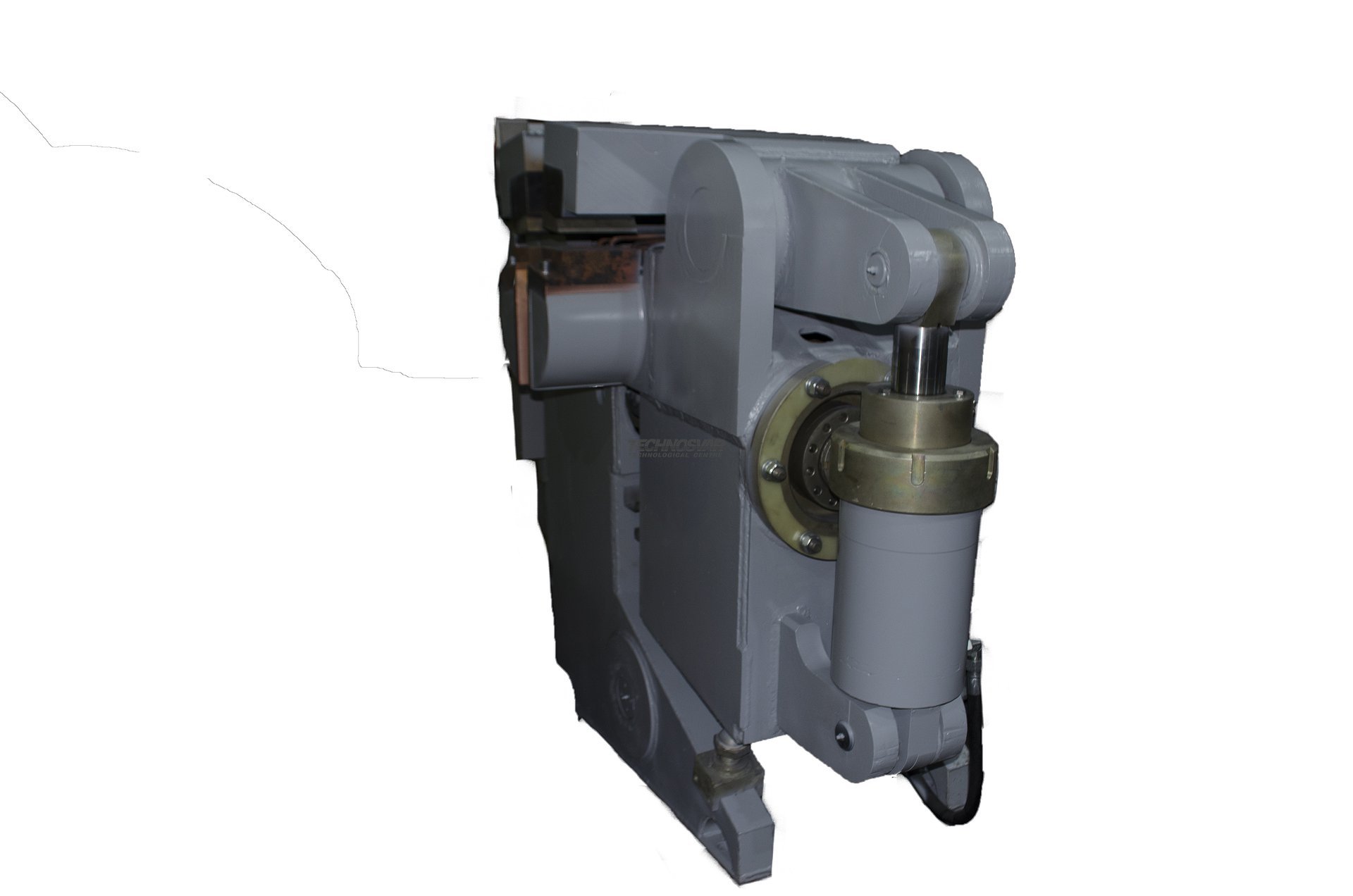

The machine K-617 for flash butt welding type MSO-1603 UHL4 is intended for flash butt welding parts from low carbon steel, austentic and heat resistant steels, aluminum alloys and copper-aluminum alloys.

The design of the machine makes it possible to weld parts of straight line or closed forms.

The design of the machine and control scheme provide the following working modes in semi-automatic cycles:

welding by cycle “continuous burn-off”

welding by cycle “burn-off with heating”.

Cooling water should conform to GOST 2874.

Additional options:

1. The machine can be equipped by the welding transformer with higher power.

2. The machine can be equipped by independent closed cooling system.

*Please pay attention that the technical specification and the appearance of the equipment placed on this web-site are only for informational purpose and are not a public offer. The producer reserves the right to make any changes.

**Copying the data without permission of the web-site administration is prohibited.