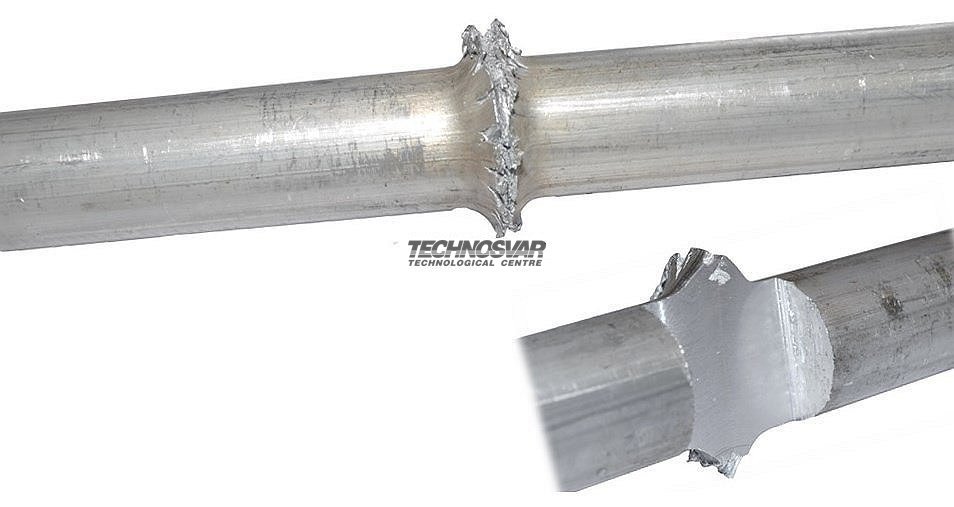

The machine MSO - 10.02 is intended for butt flash welding with continuous melting and melting with previous heating of rolled steel mainly with a compact section.

In the welding machine MSO - 10.02 (as against MSO - 10.01) the clamping force and upset force are set automatically from the control panel of operator.

Advantages of welding machine MSO-10.02:

· Up-to-date system of controlling and quality control provides continuous monitoring of actual parameters with registration and certification of each welding joint.

· The machine is equipped by automatic unit for trimming after welding in hot form (Patent No RU 2 515 864 C1)

· 20 welding programs memory storage

· Versatile process of flashing control

Additional options:

· Autonomous fluid cooling system of closed-loop type

· Possibility of version for container

· Possibility of including into automatic line LSA-01

· Welding fumes cleaning system

*Please pay attention that the technical specification and the appearance of the equipment placed on this web-site are only for informational purpose and are not a public offer. The producer reserves the right to make any changes.

**Copying the data without permission of the web-site administration is prohibited.