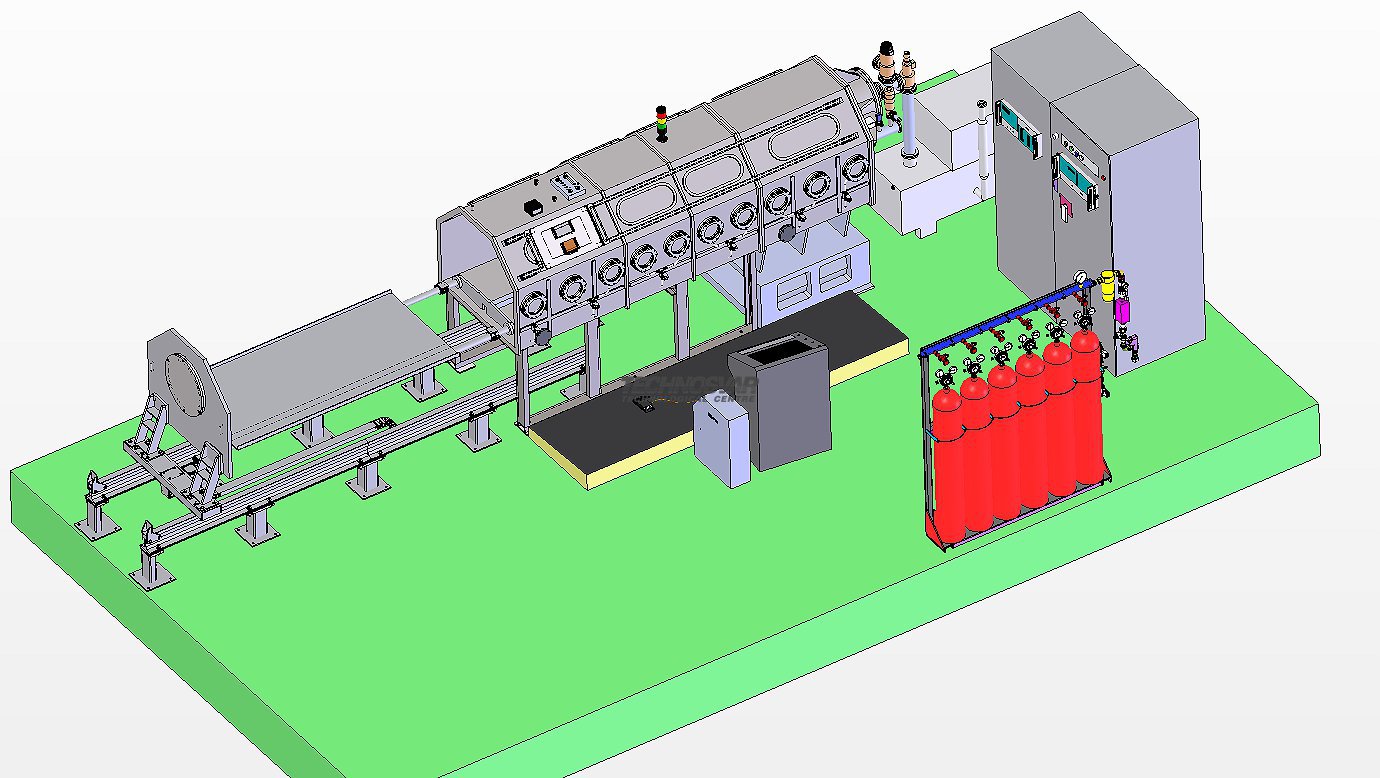

Unit УСКС-17 is designed for building controlled atmosphere in the vessel for further arc welding products made of high-melting and reactive metals (titanium and titanium alloys, zirconium, aluminum-magnesium alloys).

Advantages of unit УСКС-17

- Manual welding is performed by rubber gloves hermetically fixed in the vessel hole and burners adjusted inside the vessel

- The vessel size allows several people work simultaneously which makes it possible to weld complex parts and makes the welder’s performance easier

- Pre-handling of parts, instruments and materials is effected onto in-out table fixed on the vessel bottom

- Atmosphere control system takes automatic measurement of oxygen, hydrogenium, nitrogen and water vapour content

- Continuous gas analyzers provide for impurity content control and operating environment cleaning by inert gas substitution

The unit consists of:

- vacuum vessel

- vacuum generation system

- travelling mechanism of the vacuum system door

- welding equipment

- protective gas delivery system

- atmosphere control system detecting impurity content

- pressure balance control in glove boxes

- eye safety system during welding operations

- control systems

*Please pay attention that the technical specification and the appearance of the equipment placed on this web-site are only for informational purpose and are not a public offer. The producer reserves the right to make any changes.

**Copying the data without permission of the web-site administration is prohibited.