The unit USTK-1 is intended for manual argon-arc welding of compartments external parts from titanium alloys.

Dimensions and materials of welded units:

| compartments materials | VT20 |

| compartments diameters, mm | 360 |

| compartments length, mm | 600 |

| compartments thickness at welding area, mm | 2,5 |

| external parts max. dimensions, mm | 35х15х1,5 |

The welding unit USTK-1 consists of the following:

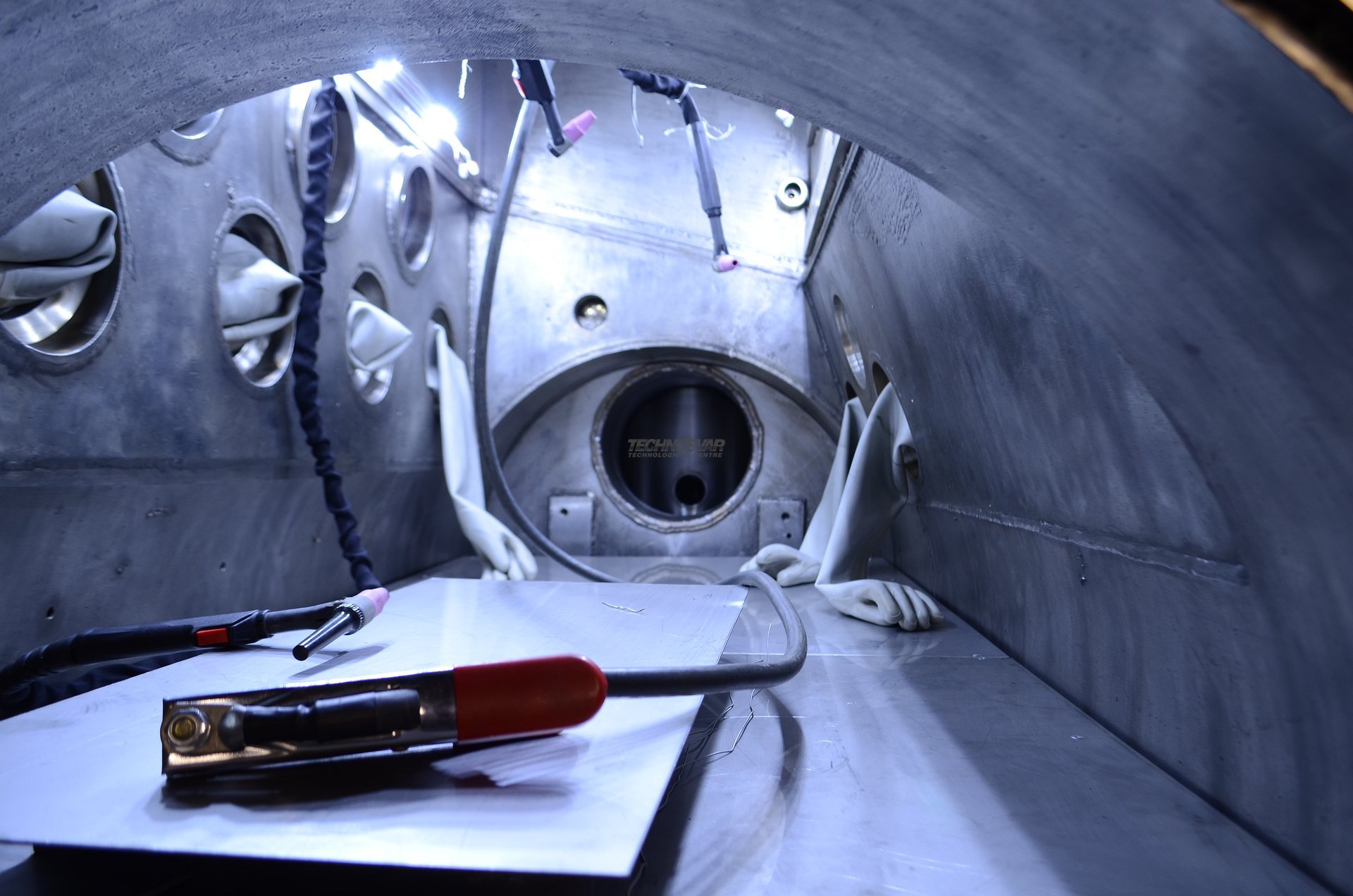

1. Vacuum chamber is a horizontal welded barrel shell with welded box positioned along generating ray on the upper side of barrel

2. The chamber has glove inlets and illuminators for watching the welding process.

3. Current lead.

4. Working table.

5. Protector for welders eyes protection.

6. Controlling-adjustment unit for automatic keeping the required argon pressure inside the vacuum chamber.

7. Lighting inside the chamber.

8. Current starting pedal.

9. Welding current controlling desk.

10. Vacuum system which consists of prevacuation and high-vacuum pumps, pipes and armature system.

11. Vacuum gauges.

12. Electric cabinet

13. Wiring

14. Safety valve for argon pressure adjustment during the inlet.

15. Control and measurement instruments station for atmospheric composition control in the working area of the vacuum chamber

(concentration of Н2О and О2).

16. Welding torches.

17. Argon filling manifold.

18. Pneumatic (hydraulic) cover clamps.

19. Mechanical cover clamps.

20. Type of source GENESIS-400.

21. Receiver for protective gas saving.

22. The chamber is fixed immovable and is not moved during parts assembling.

23. One cover of chamber is fixed tightly (without removing).

24. The second cover is sliding (for parts loading and unloading).

25. Cooling with the help of autonomous cooler (chiller).