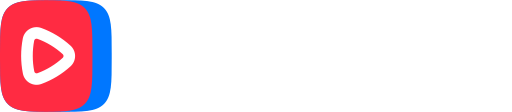

Mobile device ADFS-2001M is designed for automatic arc welding of embedded parts under a layer of flux. Welding of reinforcing steel bars of smooth and periodic profile to flat surfaces of rolled steel is exercised as back-to-back angles. ADFS device construction involves manual load of reinforcing bars, metal sheets and flux.

Dimensions of embedded parts

| Thickness of the embedded part sheet | 6 to 30 mm |

| Diameter of reinforcing bar (Class AI, AII, AIII) | 8 to 20 mm |

| Length of the reinforcing bar (Class AI, AII, AIII) | 90 to 1000 mm |

Advantages of welding device ADFS-2001M

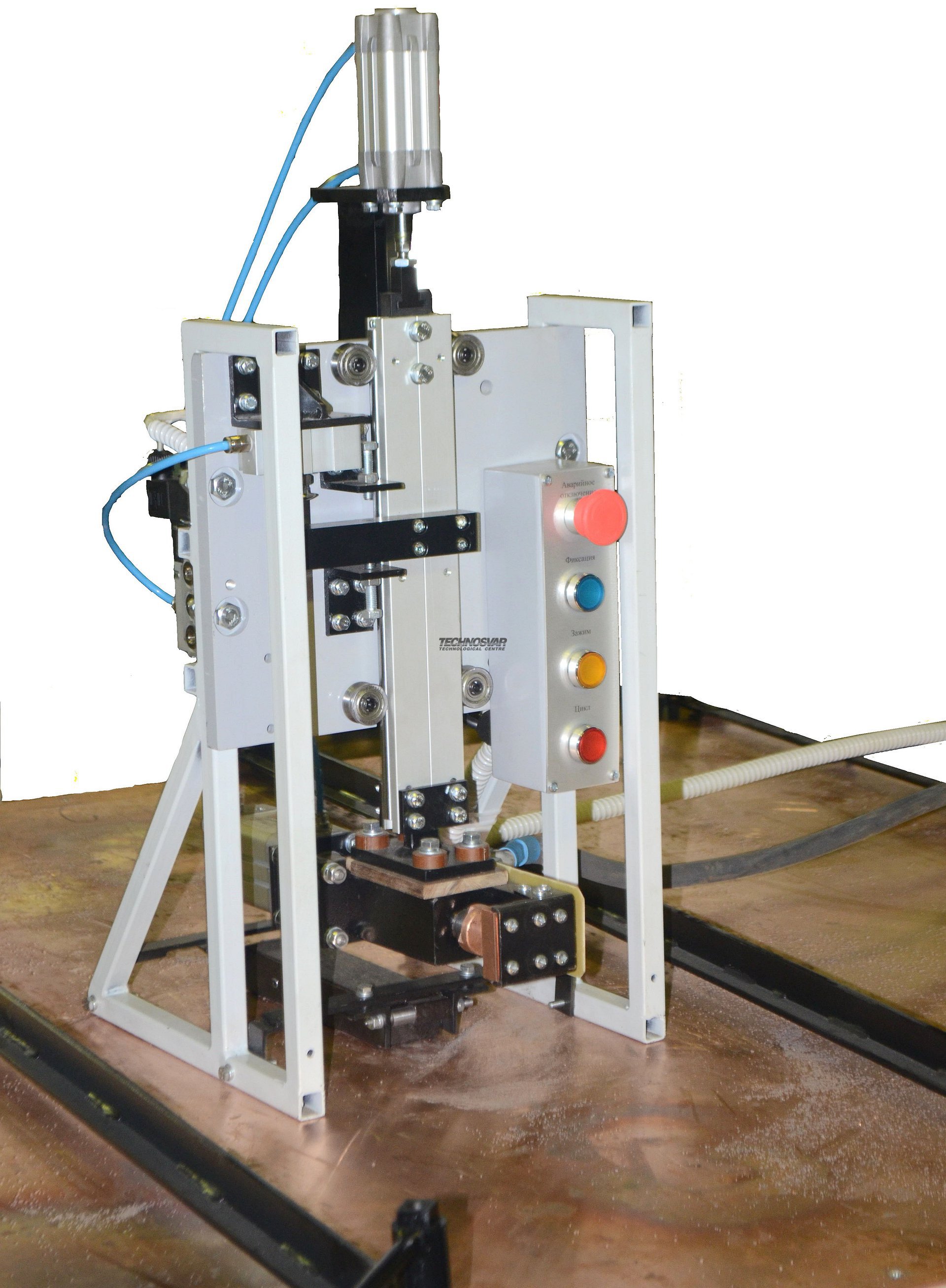

- Magnetic clamp at the base of the welding head

- The control panel on the welding head works in parallel with the remote control unit, it starts the welding process and activates the magnetic clamp to fix the welding head to the metal sheet.

- The control unit can store up to 20 welding programs in memory and use a specified cycle of operation in automatic mode:

- Feed the reinforcing bar during welding

- Turn on the welding current and turn it off after the cycle is completed.

- Ignite the arc when the rod is detached, burn the arc when the rod is fixed

- Flash upset to the bath with molten metal

- Crystallization

Composition of the welding device ADFS-2001M

- Mobile device ADFS-2001M

- Rectifier (source) of direct current, type VDU-1204

- Remote control unit

Additional options:

- Autonomous compressor device

- Inverter welding power source (welding device ADFS-2001MI)

- Flux for welding

- Optional equipment: table, assembly fixture

*Please pay attention that the technical specification and the appearance of the equipment placed on this web-site are only for informational purpose and are not a public offer. The producer reserves the right to make any changes.

**Copying the data without permission of the web-site administration is prohibited.