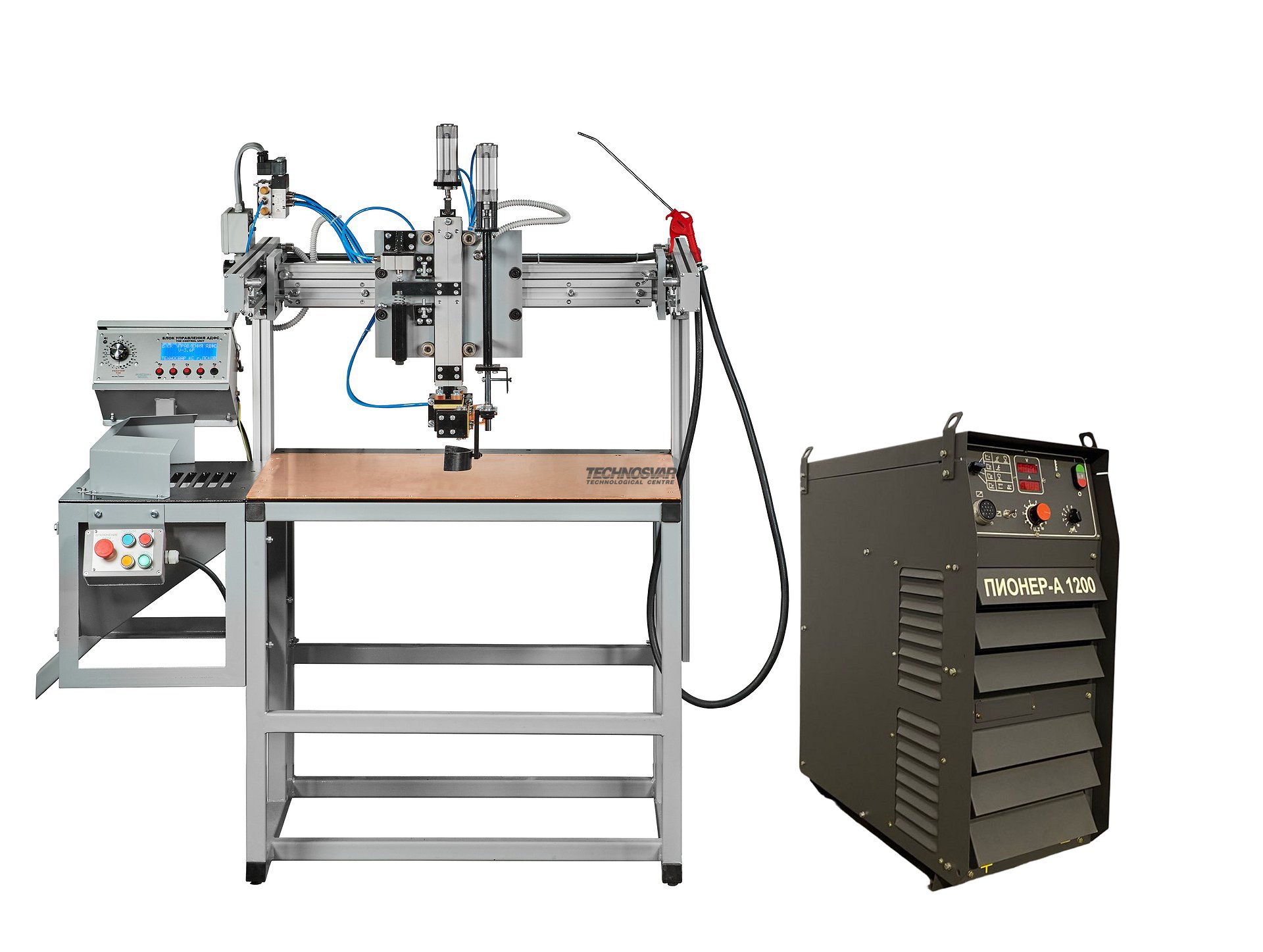

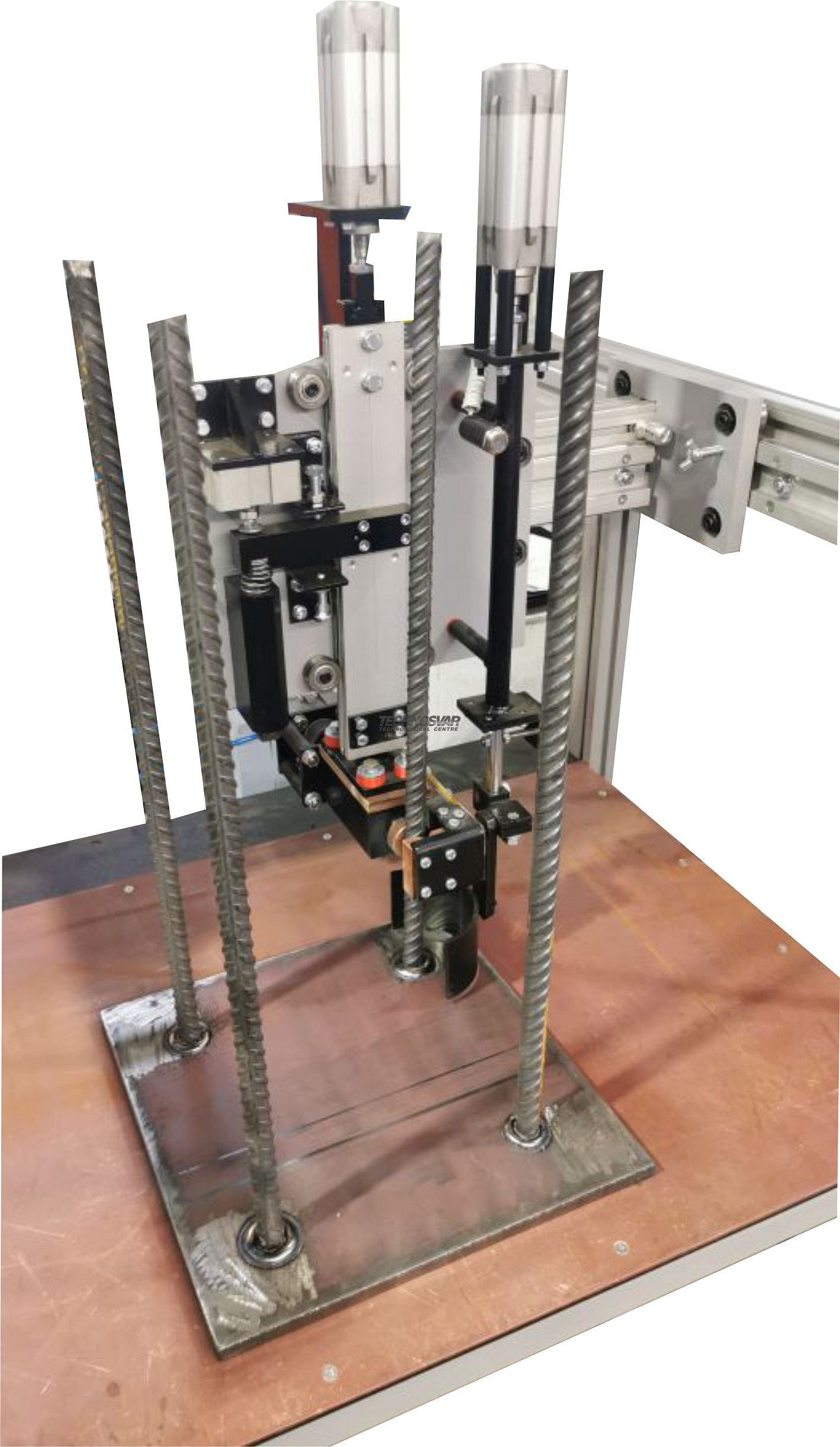

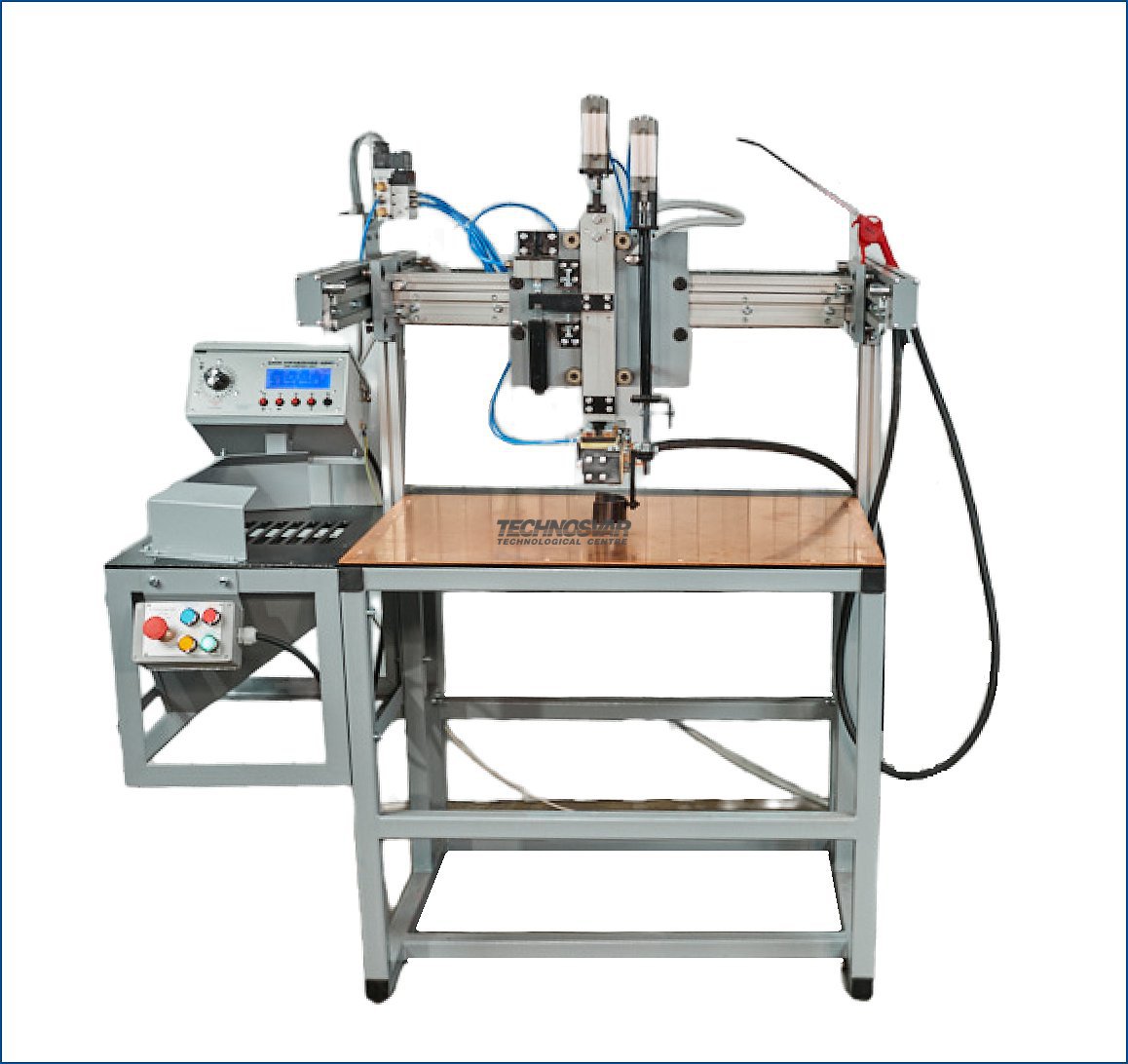

The device ADFS-2001 is designed for automatic arc welding of embedded parts under a layer of flux. Welding of reinforcing steel bars of smooth and periodic profile to flat surfaces of rolled steel is exercised as back-to-back angles. ADFS device construction involves manual load of bars, metal sheets and flux.

Dimensions of embedded parts

| Thickness of the embedded part sheet | 6 to 30 mm |

| Diameter of reinforcing bar (Class AI, AII, AIII) | 8 to 20 mm |

| Length of the reinforcing bar (Class AI, AII, AIII) | 90 to 1000 mm |

Advantages of ADFS -2001 device

- Manual horizontal movement of the bar clamping mechanism with subsequent fixation during welding, to weld anchors at given coordinates.

- Moving along axes: X - 400 mm, Y - 400 mm

- The control unit can store up to 20 welding programs in memory and use a specified cycle of operation in automatic mode:

- Feed the reinforcing bar during welding

- Turn on the welding current and turn it off after the cycle is completed.

- Ignite the arc when the rod is detached, burn the arc when the rod is fixed

- Flash upset to the bath with molten metal

- Crystallization

Composition of the welding device ADFS -2001

- ADFS -2001 device with control unit

- Rectifier (source) of direct current, type VDU-1204

Additional options:

- Autonomous compressor device

- Inverter welding power source (welding device ADFS -2001I)

- Flux for welding

*Please pay attention that the technical specification and the appearance of the equipment placed on this web-site are only for informational purpose and are not a public offer. The producer reserves the right to make any changes.

**Copying the data without permission of the web-site administration is prohibited.