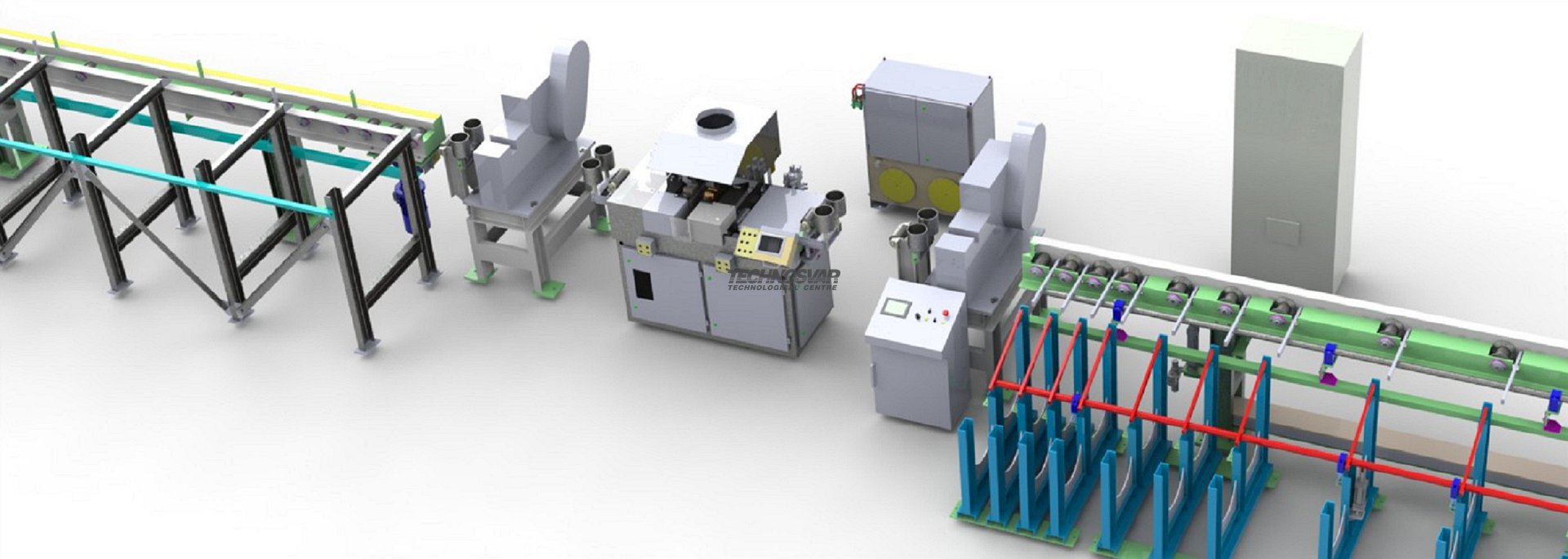

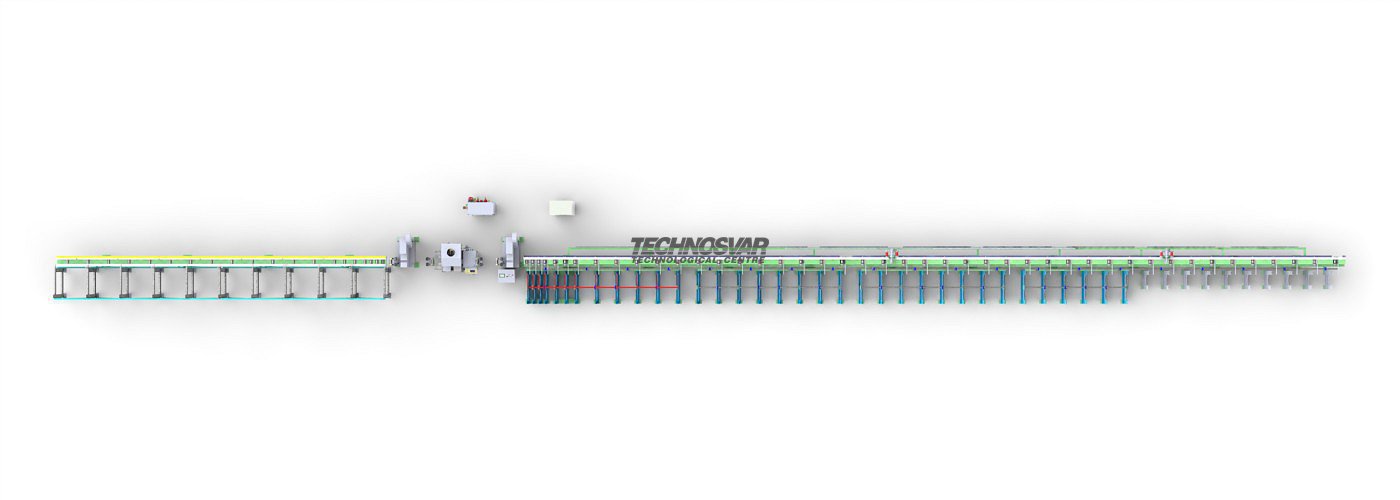

Semiautomated line of LSA-01 type is designed for producing waste-free manufacturing ofreinforcement rods and steel angles. Diameter of welding reinforcement rods is from 12 to 40 mm (class AI, AII, AIII, AIV, AV), dimensions of welding steel angles is from 20х20х3 mm to 75х75х8 mm (with ragging) and up to 100х100х6 mm (without ragging).

Advantages of semiautomated line LSA-01

- The line allows to reduce production costs and to make a workpiece of needed length

- Manual and part manual modes

- Lifting and centering roll device provides for reinforcing rod delivery to seal jaws and keeps them from premature wear

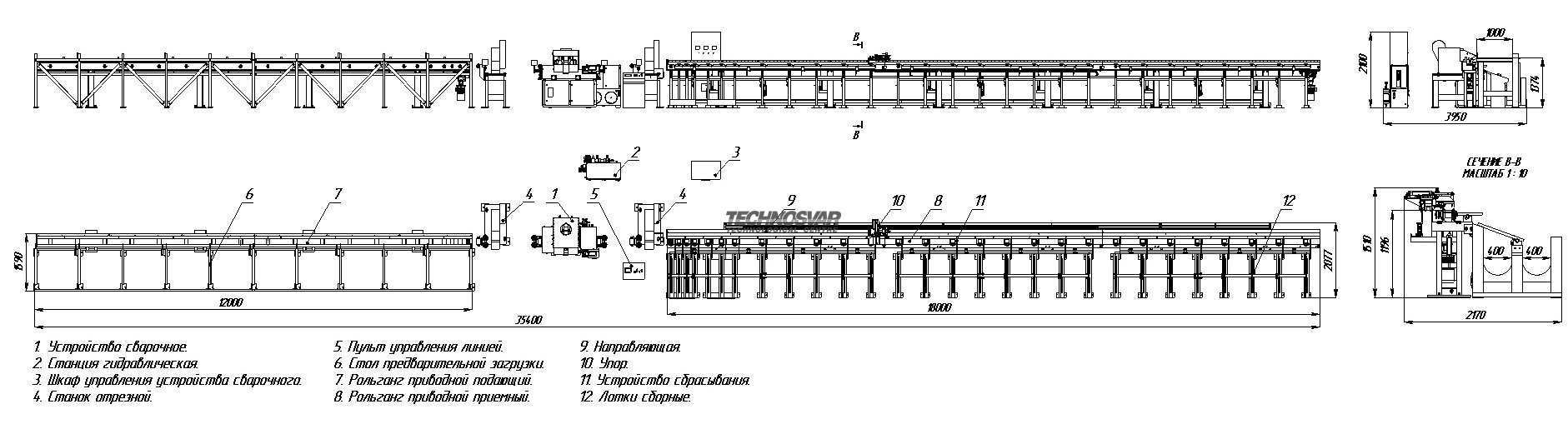

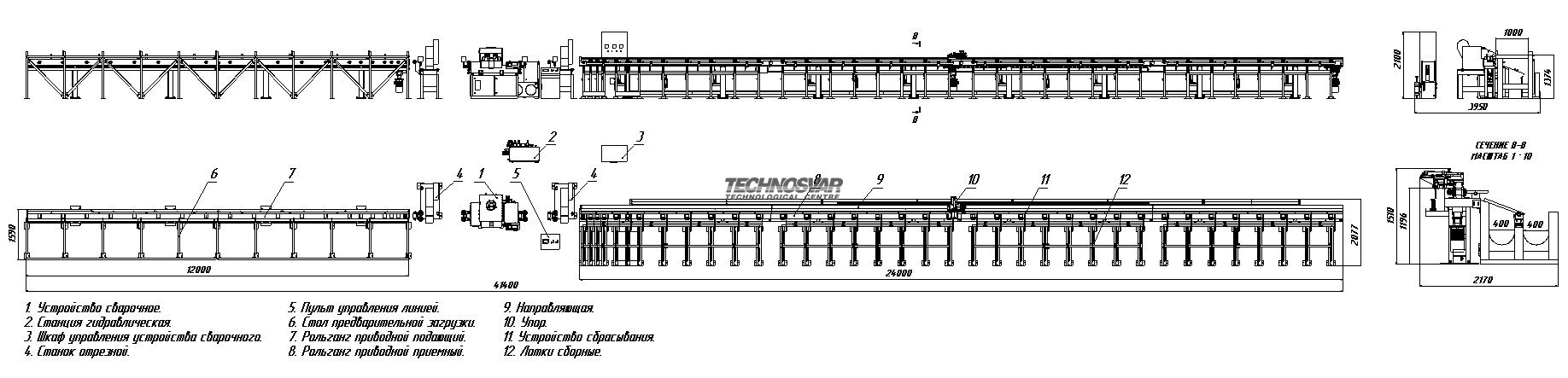

- Maximum length of bog-standard final product is 24 m (depending on reinforcing rod needed length, it is possible either to shorten or to lengthen roll table equipped with collecting tray per 6-metre length)

- Centering devices built in the line, provide for adjustment of coincidence of axes of joint welding items

- Modern controlling and quality systems provide non-stop monitoring of actual actions with storage and ticket system of up to 20 welding programs in a memory

- Welding machine, built in the line, is equipped with patented automatic device – post-welding ragging in hot position (patent № RU 2 515 864 C1)

The set is equipped:

- Butt welding machine МСО-750, МСО-12.00

- Bar cutter (cutting-to-length)

- Facing machine

- Table for reinforcement rod preload

- Feed roll-table with a drive device

- Lifting and centering device for reinforcement rods

- Cutoffmachinecenteringdevice

- Measuringdevice

- Abutment

- Clearingdevice

- Stacking tray

- Control cabinet

Additional options:

- Autonomous compressor device

- Autonomous liquid closed cooling system

*Please pay attention that the technical specification and the appearance of the equipment placed on this web-site are only for informational purpose and are not a public offer. The producer reserves the right to make any changes.

**Copying the data without permission of the web-site administration is prohibited.