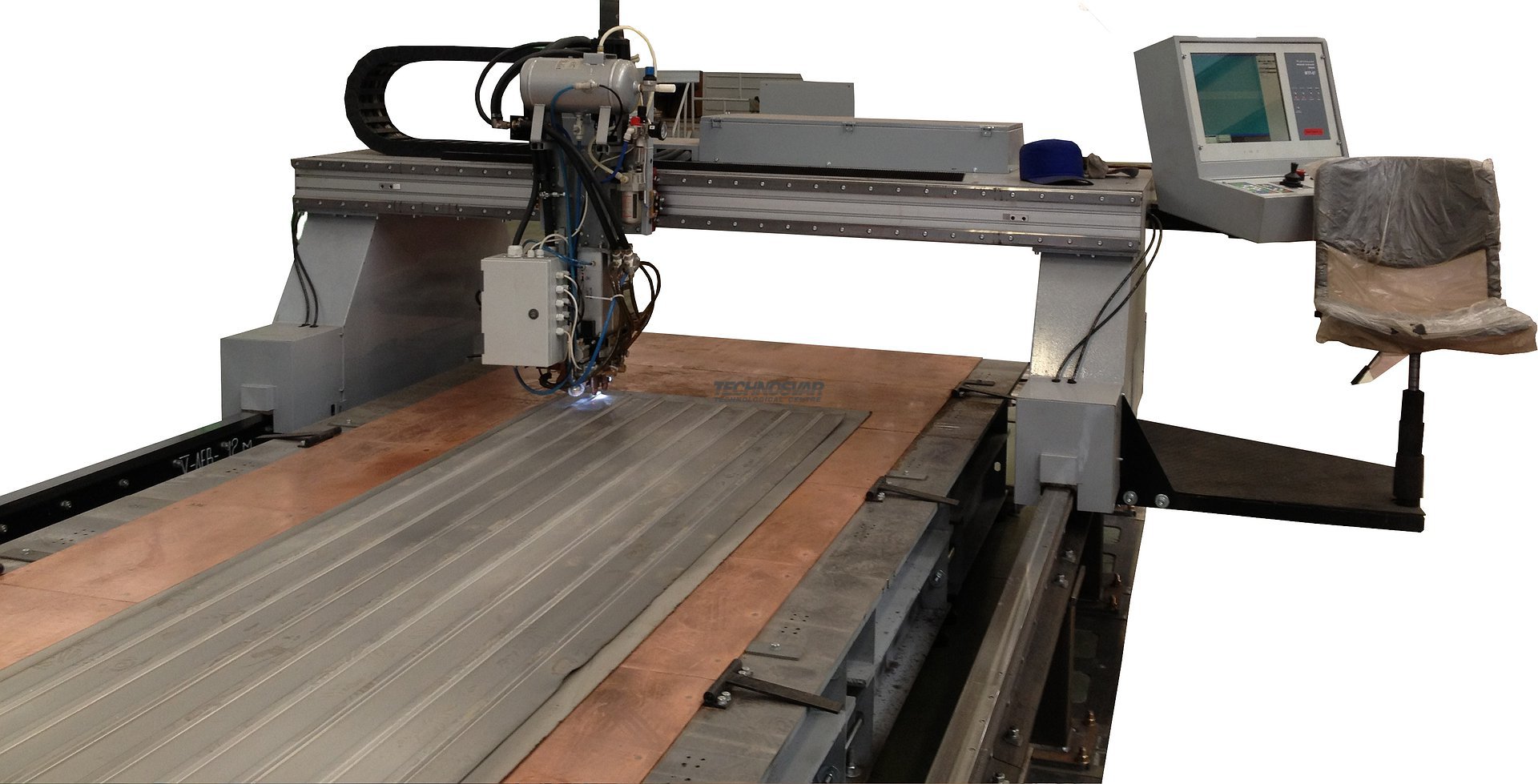

The machine is designed for single resistance spot welding of sheet and corrugated metal, without welding marks on the visual surface of the side wall panels in subway passenger cars and road-rail buses.

Welding method consists in single spot welding with two electrodes on a copper substrate.

Metals for spot welding – 12Х18Н10Т+12Х18Н10Т; 12Х18Н10Т + Ст.20. Combination of welded joint thickness values (mm): min: 0.7 + 1.0; max.: 1.5 + 2.5, in increments of 80 mm between spots.

The machine ensures welding of panels which dimensions do not exceed 1500 x 9000 mm (according to the rail track length equal to 10 m). The profile height of the welded product should not exceed 40 mm.

*Please pay attention that the technical specification and the appearance of the equipment placed on this web-site are only for informational purpose and are not a public offer. The producer reserves the right to make any changes.

**Copying the data without permission of the web-site administration is prohibited.