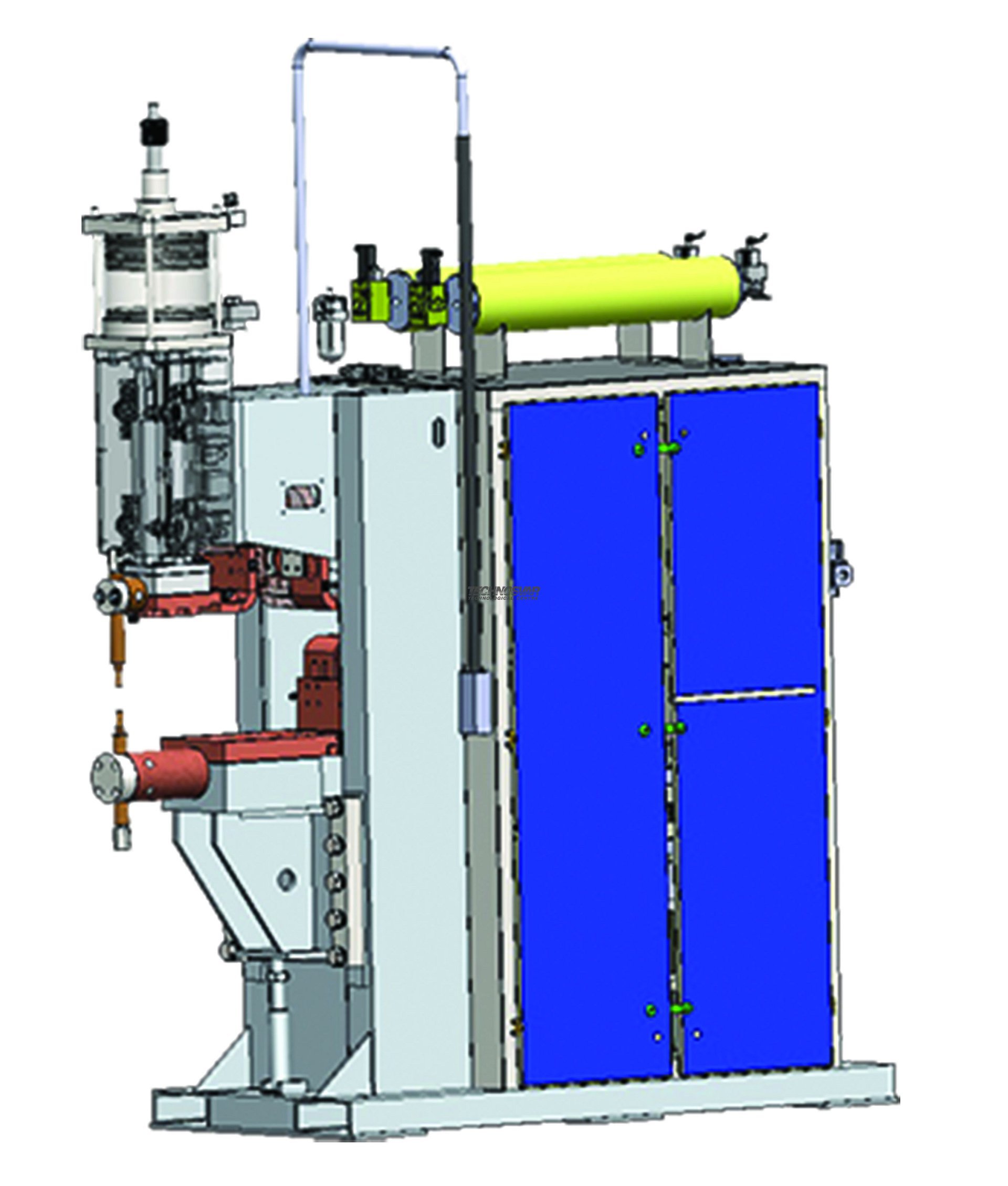

Welding machine MTV-5501 is designed for contact spot welding by direct (rectified) current of metal structures and high-duty products.

Technological capabilities of this welding machine allow welding of a wide range of products. The thickness of the material to be welded depends on the material type and quality requirements to the welded joint.

The welding machine provides the diameter of the cast core of the welded point which corresponds to production instructions of aerospace and branch instructions with the increased requirements for the quality of the welded joint.

Welding thickness ranges

| Low carbon steel | 0.5+0.5 to 5.0+5.0 mm |

| Low alloy steel | 0.5+0.5 to 3.5+3.5 mm |

| Stainless steel | 0.3+0.3 to 3.5+3.5 mm |

| Titanium alloys | 0.3+0.3 to 3.5+3.5 mm |

| Chromium-nickel alloys | 0,3+0,3 to 2,5+2,5 mm |

| Copper alloys | 0.5+0.5 to 2.0+2.0 mm |

| Aluminum alloys | 0.5+0.5 to 2.5+2.5 mm |

Advantages of the welding machine MTV-5501

- It is produced of Russian raw materials that have all the necessary certificates

- High dynamic characteristics of the drive of the welding force

- Uniform load on the grid by 3 phases

- More efficient power consumption and higher efficiency compared to AC machines

- DC power supply with 7000 A diodes

- Liquid cooling of the welding current source and secondary circuit

- The machine is equipped with a control system based on an industrial PC, which allows to:

- Differentiate the access rights of personnel (technologist / welder)

- Create and edit welding programs

- Log welding points

- Form the pulses of the welding current in the necessary shape

- Carry out a smooth and step-by-step adjustment of the welding current

- Stabilize the welding current when the mains voltage changes

Additional options:

- Autonomous liquid closed cooling system

- Autonomous compressor device

- Electrodes for contact welding of various configurations

- Assembly and welding devices

*Please pay attention that the technical specification and the appearance of the equipment placed on this web-site are only for informational purpose and are not a public offer. The producer reserves the right to make any changes.

**Copying the data without permission of the web-site administration is prohibited.